STEEL

Environments exposed to molten, acidic and high abrasion materials

STEEL equipment commonly suffers from cavitation, impingement and entrainment. These erosive forces can quickly destroy conventional coatings and lead to corrosion. we provides long-term solutions to eliminate corrosion and reduce the effects of erosion. Rudder repair and protection Rudders suffering from erosion and corrosion are repaired and improved using metal rebuilding composites and epoxy coatings.

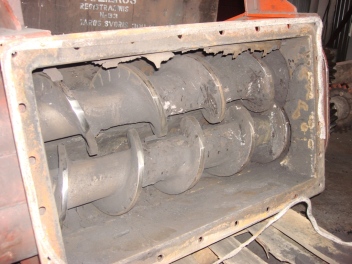

From rolling mills to blast furnaces, critical equipment in the steel industry is susceptible to abrasion, erosion, corrosion and chemical attack. , have been engineered to meet the aggressive demands of this industry. Belzona's solutions can be applied in situ and offer unmatched performance in tough application areas. Our materials have been proven to reduce downtime and labour costs as well as increase the efficiency of the plant and ensure environmental compliance. Fluid and gas handling equipment Metal repair composites can be used to protect equipment from the effects of erosion and corrosion. Simple, cold applied metal plate bonding techniques are often utilised to repair damaged pipework, using Belzona composites such as and as bonding agents. Our cold cure pipe wraps can be used to solve pipework problems and provide long-term erosion and corrosion protection. Where ISO 24817 and ASME PCC2 compliance is required, II, can be used to return strength to weakened or holed metallic surfaces whilst providing excellent corrosion protection and chemical resistance. Our fast curing emergency leak sealing systems, such as can instantly stem leaking water or gas lines preventing potentially costly implications. Belzona solvent free materials are widely used on other equipment, such as multi-stage pumps, heat exchangers, condensers and gas scrubbers. Solids handling equipment Ripped, worn and torn conveyor belts damaged by impact and abrasion can be repaired using . is ideal for restoring damaged areas to their original profile and providing outstanding protection against wear, impact and abrasion whilst eliminating the need for vulcanization. Versatile, multipurpose elastomers can also be used for simple, cost effective and long-lasting rubber repairs for equipment such as rubber rollers, flights, cleats and clip joints on conveyor belts and other rubber components. Highly abrasion resistant materials such as , are widely used to resist erosion damage and wear for equipment such as screw conveyors, chutes, hoppers and pipe sections. Storage tank and secondary containment area repair and protection Belzona provides solutions for damaged storage tanks, including emergency leak sealing and cold plate bonding. Using the fast-cure Belzona 1212 eliminates the need for hot work, greatly reducing health and safety concerns. Tank bases can be sealed with our solvent-free coatings, such as , which allow trapped moisture to escape whilst preventing water ingress at the tank base, ensuring long-term protection. Concrete floors and walls of secondary containment can be repaired and protected using the range of Belzona and . Concrete repair products, such as and , are ideal for repair and resurfacing of damaged secondary containment areas. Epoxy coatings, such as , are designed to provide long-term chemical resistance against a wide range of substances, including acids and alkalis, even at high temperatures. Shimming of worn equipment With excellent load bearing characteristics and no shrinkage, 100% solids can be used to form excellent load bearing shims. These multi-purpose materials can be used on structural supports and machinery plinths, as well as for accurate in-situ forming and shimming of wear plates, crane rails and rail tracks. Precise alignment and anchorage of heavy equipment can be achieved using the chocking, backing and levelling compound Belzona 7111 (Industrial Grade). This pourable material resists pressure, impact and vibrations, providing a reliable foundation for heavy machinery and equipment. Facilities maintenance Belzona provides a cost-effective solution to maintenance problems by minimising downtime, labour, and equipment replacement costs, whilst simultaneously optimising the efficiency and reliability of facility assets. We can provide solutions for the repair and protection of your facility, including: for weatherproofing buildings, structures and insulation to protect against and reduce environmental impact for the prevention of slips and to provide positive grip

STEEL Industry Products

Erosion Protection

Metal Repair/Rebuilding

ACID Corrosion Protection

Some of our customers

YSP-2011 AND 2015 - Epoxy adhesive with mechanical strength and high fatigue resistance

A two component fatigue resistant adhesive, optimized for structural bonding applications requiring high mechanical strength, cleavage and shear resistance. Suitable for typical wed and dry service applications up to 60 C (140 F). for use in original equipment manufacture or repair situations.

YSP 2011 and 2015

CLOSE

YESCHEMI ® FRP are glass fiber reinforced lining systems that can be applied to both steel and concrete substrates and are suitable for chemically and mechanically stressed areas.

FRP laminate systems are used to seal reinforced concrete and recovery basins when storing liquids, indoors and outdoors or as a flooring product. FRP systems are subdivided according to their resin base. These include Vinyl-Ester, Furan, Phenolic and Epoxy resin systems, which are used depending on the particular process conditions.