YSP-400

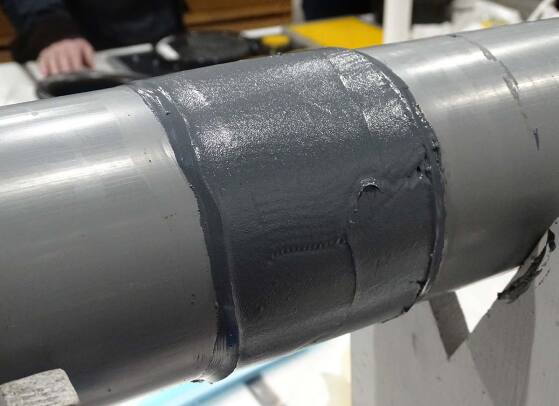

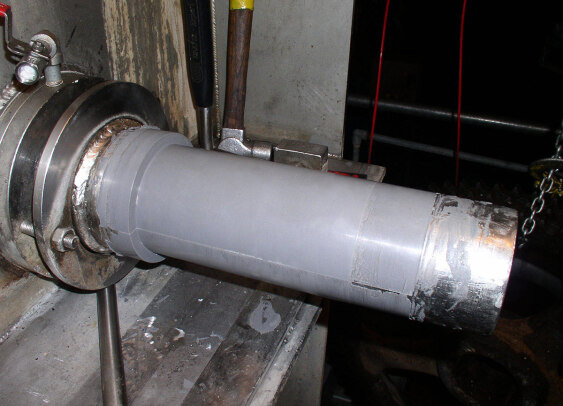

The basis of these coatings is based on the use of hybrid polymers reinforced with ceramic particles and multi-component hardeners. These coatings are solvent-free and the environmental curing mechanism reduces equipment downtime. These coatings have very high abrasion resistance and ceramic fillers are used. The advantages of using these coatings are as follows:

Product Benefits

Corrosion protection of high temperature equipment suitable for continuous immersion up to 140°C and 220°C dry

Excellent chemical resistance to a wide range of hydrocarbons and amines, sulfur compounds

Application by gun and spray or repair mortar

o Possibility of environmental curing and application at high temperatures (post-curing is performed in service)

o Excellent adhesion and very high corrosion resistance

o Fast-curing coating at ambient temperature

Easy repairability and even the ability to repair other coatings such as rubber lining and glass lining

Single-layer and solvent-free

The definitive solution for protecting metal and concrete surfaces against severe chemical and thermal conditions

Reduces downtime due to innovative post-curing mechanism that is activated at service temperature - maximum curing time is achieved without the need for separate post-curing.

Product Categories

Ceramic coatings are divided into three application categories.

• Ceramic coatings with low temperature tolerance up to 50 degrees in immersion

• Ceramic coatings with medium temperature tolerance up to 95 degrees in immersion

• Ceramic coatings with medium temperature tolerance up to 140 degrees in immersion, which includes temperatures of 110 degrees, 125 degrees, 140 degrees.

These products are also used as repair mortars and sprayable coatings. The matrix of these coatings can be used with glass flakes.

Chemical resistance of chemical tank covers

Amines (DEA, MDEA, MEA, DGA, ADIP) Spent amines rich in H2S/CO2

• 98% Sulfuric acid 37% Hydrochloric acid

• 100% Glacial acetic 50% Nitric acid

• Methylene chloride, vinyl chloride, benzyl chloride, carbon disulphide

• Molten Sulfur + acidic vapor Conc. Methanol, ethanol and derivatives

• Sodium hypochlorite, sodium perchlorate MEK, Toluene, Xylene, Acetone, Ammonia

• 50-75% Sodium Hydroxide Mono and triethylene glycol at all concentrations

YSP-2011 AND 2015 - Epoxy adhesive with mechanical strength and high fatigue resistance

A two component fatigue resistant adhesive, optimized for structural bonding applications requiring high mechanical strength, cleavage and shear resistance. Suitable for typical wed and dry service applications up to 60 C (140 F). for use in original equipment manufacture or repair situations.

YSP 2011 and 2015

CLOSE

YESCHEMI ® FRP are glass fiber reinforced lining systems that can be applied to both steel and concrete substrates and are suitable for chemically and mechanically stressed areas.

FRP laminate systems are used to seal reinforced concrete and recovery basins when storing liquids, indoors and outdoors or as a flooring product. FRP systems are subdivided according to their resin base. These include Vinyl-Ester, Furan, Phenolic and Epoxy resin systems, which are used depending on the particular process conditions.

YESCHEMI

YSP-FRP Lining

CLOSE

سیستمهای پوششی تقویتشده با الیاف شیشه هستند که میتوانند هم روی بسترهای فولادی و هم بتنی اعمال شوند و برای مناطق تحت تنش شیمیایی و مکانیکی مناسب هستند.

سیستم های لمینت FRP برای آب بندی بتن مسلح و حوضچه های بازیابی در هنگام ذخیره سازی مایعات، در داخل و خارج از منزل یا به عنوان یک محصول کف سازی استفاده می شود. سیستم های FRP بر اساس پایه رزینی خود تقسیم بندی می شوند. اینها شامل سیستم های وینیل استر، فوران، فنولیک و رزین اپوکسی است که بسته به شرایط فرآیند خاص استفاده می شود.